CNC Vertical Machining Services

At Jessen, our CNC vertical machining process combines knowledge, resourceful thinking, plus expertise of machinists and technicians to produce quality parts. Through vertical milling, we are able to produce a refined shape or finish on any bar stock, plate, or block of material.

3-axis CNC Vertical Machining Centers that we use are best suited to perform heavy milling work. The embedded automation of our CNC machining center ensures a high level of dimensional control and accuracy in every piece produced. With a spindle speed capable of 15000 rpm, the machine can mill, drill and rigid tap with great speed and precision. The 32-position tool changer options allow for automatic tooling changes during the shaping process to achieve the required profiles, depths and dimensions of the part design. This ensures reduced cycle time, along with part consistency and uniformity in all components.

Since all tools and fixtures are engineered and manufactured in-house to produce your product, we provide quick turnaround time for our customers. Additionally, the machined parts can be ground, vibratory-finished, heat-treated or plated according to customer requirements.

Use the “Request Information” selection to contact us. Attach your design documentation along with your contact information for our Engineering Department to review and provide you with a quote.

- Machine Specifications:

- ISO Certifications:

ISO 9001:2015 Certification

See the right hand navigator for “Downloads”.

- Tolerances the machines can produce repeatedly:

0.0004 inch

- Quantity of Parts Produced:

We can produce prototype parts of one, to high volume production quantities.

- Equipment List

(1) Okuma M560-V 15K

(1) Hardinge Conquest V1000

(3) Tree-Kira 10 tool CNC tap/mill machine centers, Model VTC-30

- Materials & Supporting Documentation:

- Acceptable Drawing File Formats

PDF, JPG, JPEG, BMP, TIF, TIFF, DXF, DWG, GIF, PCX, WPG.

- Materials Worked:

Metals and Alloys:

but NOT limited to….

Free Machining and Medium Carbon Steels

Alloy Steel

Tubing

Stainless

Brass

Aluminum

Copper

Bronze

Iron (grey and ductile)

Tool Steels

Drill Rod

Monel

Inconel

Hastaloy

Titanium

Kovar

Pinion Rod

Black Pipe

Plastics:

but NOT limited to….-PVC

-nylon

-delrin

-ultem

-peek

-acetal

-phenolic

-teflon

-nylatron

-noryl

-polyethylen uhmx

- General Specifications:

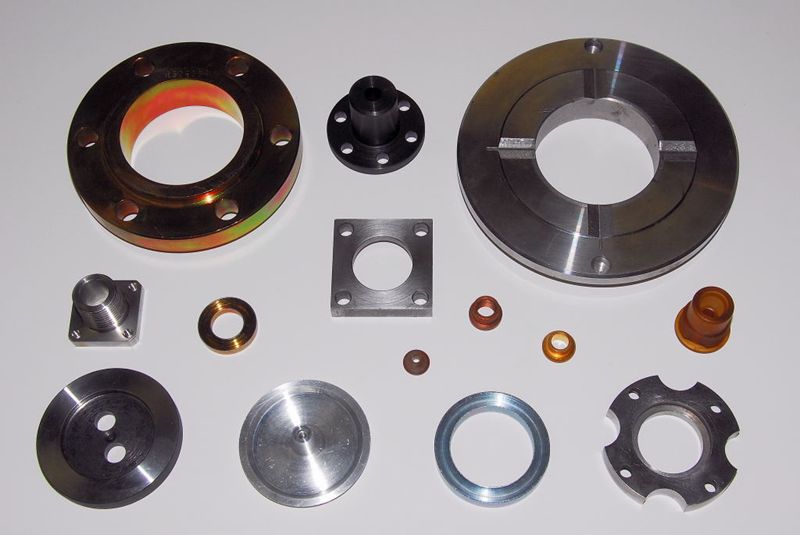

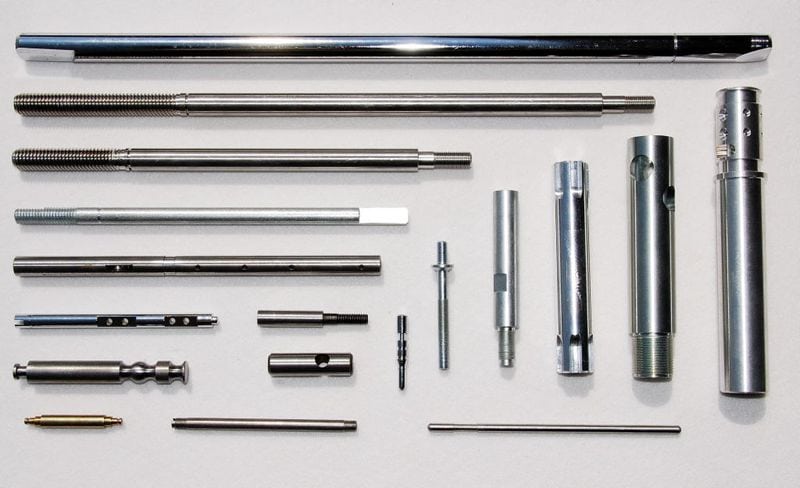

- Parts Typically Produced:

Actuator Shafts, Adapters, Adjusting Bolts, Air Regulators, Anchors, API Flanges, Back-Up Flanges, Balls, Ball Swivels, Barbed Fittings, Barrels, Bearing Locking Rings, Blind Flanges, Bolts, Bushings, Cable Glands, Cable Retainers, Caps, Cap Nuts, Cap Screws, Cases, Check Needles, Check Valves, Check Valve Bodies, Clevis’, Closed-End Inserts, Collars, Connector Housings, Contacts, Covers, Crimp Sleeves, Double-Ended Studs, Dowels, End Caps, Extenders, Ferrules, Gear Blanks, Glands, Gland Nuts, Handles, Head Poppet Stems, Hose Connectors, Housings, Knobs, Knurled Inserts, Lap Joint Flanges, Levers, Molded Inserts, Nipples, Notched Inserts, Open-End Inserts, Pinion Rods, Pins, Pistons, Piston Seats, Piston Stems, Plungers, Pole Faces, Poppets, Ports, Prongs, Push Buttons, Quills, Raised Face Flanges, Release Screws, Release Tube Flanges, Retainers, Rivets, Rods, Rollers, Scrapers, Seal Rings, Seats, Self Tapping Inserts, Sleeves, Slip-On Flanges, Shafts, Shoulder Bolts, Shunts, Socket Weld Flanges, Spacers, Split Collars, Spools, Spool Stops, Spring Guides, Spring Retainers, Standoffs, Stems, Tapered Insert, Threaded Flanges, Threaded Inserts, Threaded Rods, Threaded Studs, Tubes, Valves, Valve Caps, Valve Stems, Welded Neck Flanges, etc.

- Industries Served:

Agricultural

Hydraulic/Fluid power

Electronics

Heavy Equipment

Automotive

Industrial

Heavy Duty Trucks

Medical Instruments

Marine Industry

Military

Brake Parts

Oil & gas industry

Plumbing

Fasteners

Injection Molding

Machinery and Equipment

Fasteners

Construction

Mass Transit

Lawn and Garden

Recreation Equipment

Heating/Refrigeration

Food/Beverage

Mining Equipment

Water Treatment