CNC Turning Services

For nearly 100 years, Jessen has grown to become one of the world’s largest suppliers of precision CNC machined products. We have done this by committing to excellence throughout the company; a team –oriented approach to creating innovative manufacturing solutions and using only the most advanced equipment and technologies. Our Okuma CNC lathes are equipped with sub spindles for back working operations, multi axis turrets, live tooling, (for drilling, milling and turning operations) and bar feeder’s capable of up to 3 1/8”stock and chucking capacity up to 14”. Utilizing the live tools, Jessen can hold critical geometric tolerances by eliminating re-chucking of the parts and completing them in only one competitive operation. We provide CNC turning of stainless steel, copper, aluminum, carbon and alloy steels, brass, bronze, plastic and many other exotic materials.

We also offer ID and OD Hard Turning on parts starting at 45 Rc and higher, providing tolerances and micro finishes historically associated with grinding. Common hard turned materials include tool, bearing and case-hardened steels, as well as all other metallurgical challenging materials. Hard turning eliminates operations and can provide substantial cost savings.

Use the “Request Information” selection to contact us. Attach your design documentation along with your contact information for our Engineering Department to review and provide you with a quote.

- Machine Specifications:

- ISO Certifications:

ISO 9001:20015Certification

See the right hand navigator for “Downloads”.

- Tolerances the machines can produce repeatedly:

0.0004 inch

- Quantity of Parts Produced:

We can produce prototype parts of one, to high volume production quantities.

- Equipment List

(14) Okuma CNC Lathes with bar feeders. Bar capacity range from 3/8″ thru 3-1/ 8″.

Slug capacity range from 1/4″ thru 15″.

(1) # LB12

(4) # LB15

(1) # LB15 II Long Bed

(1) # LC20 4 Axis

(1) # L370 – BB Captain

(2) # L370 CNC Lathe with sub spindle & live tooling

(1) # LU15 MW 4 Axis CNC Lathe with sub spindle & live tooling

(1) # LB25 Long Bed CNC Lathe

(1) Okuma GENDS CNC Lathe with sub Spindle & live tooling

(1) Okuma LB3000EX II/800 MYW CNC Lathe with sub Spindle & live tooling

- Materials & Supporting Documentation:

- Acceptable Drawing File Formats

PDF, JPG, JPEG, BMP, TIF, TIFF, DXF, DWG, GIF, PCX, WPG.

- Materials Worked:

Metals and Alloys:

but NOT limited to….Free Machining and Medium Carbon Steels

Alloy Steel

Tubing

Stainless

Brass

Aluminum

Copper

Bronze

Iron (grey and ductile)

Tool Steels

Drill Rod

Monel

Inconel

Hastaloy

Titanium

Kovar

Pinion Rod

Black Pipe

Plastics:

but NOT limited to….-PVC

-nylon

-delrin

-ultem

-peek

-acetal

-phenolic

-teflon

-nylatron

-noryl

-polyethylen uhmx

- General Specifications:

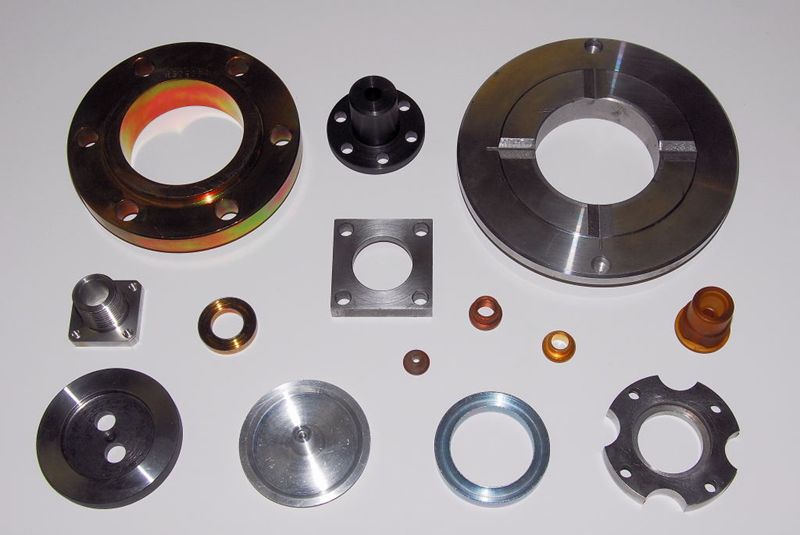

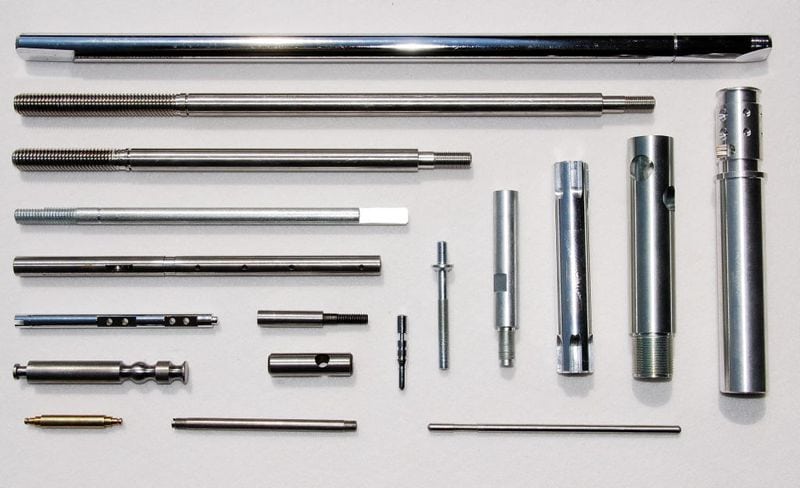

- Parts Typically Produced:

Actuator Shafts, Adapters, Adjusting Bolts, Air Regulators, API Flanges, Anchors, Back-Up Flanges, Balls, Ball Swivels, Barbed Fittings, Barrels, Bearing Locking Ring,Blind Flange, Bolts, Bushings, Cable Glands, Cable Retainers, Caps, Cap Nuts, Cap Screws, Cases, Check Needles, Check Valves, Check Valve Bodies, Clevis’, Collars, Connector Housings, Contacts, Covers, Crimp Sleeves, Double-Ended Studs, Dowels, End Caps, Extenders, Ferrules, Gear Blanks, Glands, Gland Nuts, Handles, Head Poppet Stems, Hose Connectors, Housings, Knobs, Lap Joint Flanges, Levers, Molded Inserts, Nipples, Pinion Rods, Pins, Pistons, Piston Seats, Piston Stems, Plungers, Pole Faces, Poppets, Plungers, Ports, Prongs, Push Buttons, Quills, Raised-Face Flanges, Release Screws, Release Tube Flanges, Retainers, Rivets, Rods, Rollers, Scrapers, Seal Rings, Seats, Sleeves, Shafts, Shoulder Bolts, Shunts, Slip-On Flanges, Spacers, Split Collars, Spools, Spool Stops, Spring Guides, Spring Retainers, Socket Weld Flanges, Standoffs, Stems, Tapered Inserts, Threaded Flanges, Threaded Inserts, Threaded Rods, Threaded Studs, Tubes, Valves, Valve Caps, Valve Stems, Welded Neck Flanges, etc.

- Industries Served:

Agricultural

Hydraulic/Fluid power

Electronics

Heavy Equipment

Automotive

Industrial

Heavy Duty Trucks

Medical Instruments

Marine Industry

Military

Brake Parts

Oil & gas industry

Plumbing

Fasteners

Injection Molding

Machinery and Equipment

Fasteners

Construction

Mass Transit

Lawn and Garden

Recreation Equipment

Heating/Refrigeration

Food/Beverage

Mining Equipment

Water Treatment