Turnkey Process Services

Highly efficient heat-treating, coating, and assembly services for CNC and screw machined products are part of our turnkey offerings. We provide exceptional service, which meet or exceed client’s design requirements with partners who are ISO or QS certified.

Light assembly work is one of our specialties. We press inserts/bushings into parts and sub-assemblies as well as assemble O-rings into seals & glands. The final kitting or packaging activity is carried out using either custom parts or vendor-supplied components. We also package service and repair kits.

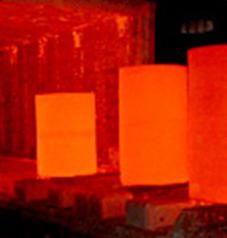

Heat-treating options by our partner suppiers at Jessen, are vast and include special case hardening as well as vacuum heat-treating. The process uses the latest equipment, from mesh belt furnaces to dissociated ammonia generators, for producing the desirable mechanical strength in the parts. Performed under controlled environments, these thermally processed parts can withstand different operating conditions.

Our partner suppiers perform electro and electroless deposition plating for most products by barrel or rack processes, electropolishing, and industrial etching. With technical knowledge on different plating processes and its ASTM/ Mil-spec standards, our plating partners can provide durable, hard, as well as precision plating solutions.

Jessen’s partner suppliers also provides powder coating and specialized wet paint coating services. Coatings are provided based on application requirements, be it corrosion resistance, wear resistance, non-stick, or friction reducing coatings in automated, negatively charged booth spray and box ovens.

These are services performed by our outside partner suppliers, who control the desired results to meet and or exceed our clients design requirements for the following processes:

- Heat Treating Processes:

- Induction, Case, & Through Hardening, Annealing & Stress Relieving, Thermal Processing, Nitriding, Brazing, Vacuum Heat Treating, Cryogenics, etc.

- Coatings:

- Plating:

Zinc, Cad, Trivalent Zinc, Trivalent and Hexavalent chrome, Decretive Chrome, Hard Chrome, Hardcoat, Anodize, Black Oxide, Passivation, Electroless Nickel, Nickel, Zinc and Manganese Phosphate, Silver, Copper, Zinc-Nickel Alloy, etc. - Painting Wet Spray:

Providing a durable finish with the ability to color match your product, or design needs. - Powder Coatings:

Painting, Solid and Dry Film Lubricants, Chemical Conversion Coatings, Teflon, Corrosion Resistant Coatings, Wear Resistant Coatings, Friction Reducing Coatings, Military Specifications Coatings, Non-Stick Coatings, 3M Scotch-Grip Fastener Adhesive, 3M Brand Thread Sealant, Loctite, Dri-Loc, Biwax, Liquid Nylon, Nylon Patch, FCT 343 HT Thread Jammer, etc.

- Plating:

Use the “Request Information” selection to contact us. Attach your design documentation along with your contact information for our Engineering Department to review and provide you with a quote.

- Machine Specifications:

- ISO Certifications:

ISO 9001:2015 Certification

See the right hand navigator for “Downloads”.

- Quantity of Parts Produced:

We can produce: prototype parts of one, to high volume production quantities. Or support vendors work with us to keep a steady flow of components in our inventory control system.

Their production quantities are subject to part size and processes required.

- Equipment List

Equipment used to support these Turnkey Processes:

Heat-Treating:- Box Furnaces

- Roller Hearth Furnaces

- Mesh Belt Furnaces

- IQ Furnaces

- Endothermic Generators

- Exothermic Generators

- Dissociated Ammonia Generators

Plating Service Type:- Electro & Electroless deposition

- Submersion Tank Plating

- Anodization

- Chrome plating

- Electrochemistry

- Electropolishing

- Gilding

- Industrial etching

- Submersion Tank Plating

Powder Coating application and Polymers Used:- Negative Charged Booth Spray and Box Oven

- Powder Coating and Oven Automated Line

- acrylics

- polyester

- polyester-epoxy (known as hybrid)

- straight epoxy (Fusion bonded epoxy)

Wet Paint Coating Types:- Paint Spray Booth

- Paint Spray Line

- Testing Process

Hardness Testing

Surface Testing

- Materials & Supporting Documentation:

- Acceptable Drawing File Formats

PDF, JPG, JPEG, BMP, TIF, TIFF, DXF, DWG, GIF, PCX, WPG.

- Materials Worked:

Metals and Alloys:

but NOT limited to….

Free Machining and Medium Carbon Steels

Alloy Steel

Tubing

Stainless

Brass

Aluminum

Copper

Bronze

Iron (grey and ductile)

Tool Steels

Drill Rod

Monel

Inconel

Hastaloy

Titanium

Kovar

Pinion Rod

Black Pipe

Plastics:

but NOT limited to….

-PVC

-nylon

-delrin

-ultem

-peek

-acetal

-phenolic

-teflon

-nylatron

-noryl

-polyethylen uhmx

- General Specifications:

- Industries Served:

Agricultural

Hydraulic/Fluid power

Electronics

Heavy Equipment

Automotive

Industrial

Heavy Duty Trucks

Medical Instruments

Marine Industry

Military

Brake Parts

Oil & gas industry

Plumbing

Fasteners

Injection Molding

Machinery and Equipment

Fasteners

Construction

Mass Transit

Lawn and Garden

Recreation Equipment

Heating/Refrigeration

Food/Beverage

Mining Equipment

Water Treatment