Secondary Services

Jessen’s use of Lean cellular manufacturing, exceptional engineering, in-house tool making and efficient production all come together to provide Just-in-Time delivery for customers in a variety of industries. The types of materials handled include carbon and alloy steel, brass, bronze, copper, aluminum, plastic, stainless steel and most other exotic materials.

We meet our customers’ needs… from prototype short production runs to high volume production quantities. Parts range from the basic to the most complex ones.

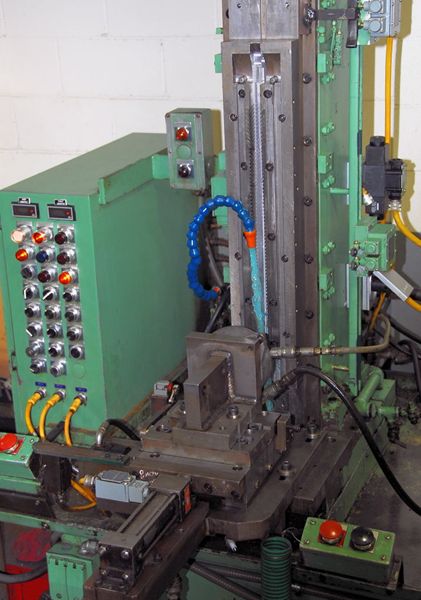

Services provided, but not limited to include: Broaching, Grinding, Honing, Conventional Milling, Reaming, Slotting, Thermal Deburring, EDM services, Stamping, Staking, Bending, Thread Rolling, Forming, Tapping, Vibratory Finishing, Machining of gear racks, and light assembly, etc.

We provide a complete part from start to finish. Contact Us if you have a need for one of these services outside our normal production.

Use the “Request Information” selection to contact us. Attach your design documentation along with your contact information for our Engineering Department to review and provide you with a quote.

- Machine Specifications:

- ISO Certifications:

ISO 9001:2015 Certification

See the right hand navigator for “Downloads”.

- Tolerances the machines can produce repeatedly:

Honing: 0.0002 inch with a number 4 micron Surface Finish

Broaching: 0.0004 inch

Centerless Grinding: See Equipment List Below

- Quantity of Parts Produced:

We can produce: prototype parts of one, to high volume production quantities.

- Equipment List

Broaching Department:

(1) Miles Horizontal Hydraulic Broach

36″ Stroke x 5 Ton/High Speed Operation

1) Detroit Horizontal Hydraulic Broach

60″ Stroke x 8 Ton/High Speed Operation- Available Broaching Shapes are:

“Sizes should be confirmed at inquiry”

For Internal Profiles:- Keyway – Square Profiles

- Splines and Keyways Profiles

- “D” & Double “D” Profiles

- For External Profiles:

- Slots

- Gear & Tooth Profiles

- Angles & Flat Profiles

Grinding Department:

(3) Cincinnati centerless grinders, Model # 2

(1) Sunnen hone, Model # 1804

Secondary Operations:

(2) Miles & Detroit horizontal hydraulic broach

(2) Snow automatic single and 2-spindle drilling/tapping machines

(8) Milwaukee production milling machines

(3) Dumore multi station drilling machines

(3) Hardinge super precision bench lathes

(1) Clausing lathe

(1) 12″ Automatic Clausing bandsaw

(20) Drill presses

Various other equipment including marking presses, arbor presses, belt sanders, polishing and buffing machines, etc.

Parts Cleaning Equipment:

(1) Ramco parts wash/ rinse/ dry line system including ultrasonic cleaning

(1) McKenzie Floor Type Chip Separator

(1) Fourway 2 Stage parts washing system

(1) Empire abrasive air-blast deburring system- Available Broaching Shapes are:

- Materials & Supporting Documentation:

- Acceptable Drawing File Formats

PDF, JPG, JPEG, BMP, TIF, TIFF, DXF, DWG, GIF, PCX, WPG.

- Materials Worked:

Metals and Alloys:

Free Machining and Medium Carbon Steels

Alloy Steel

Tubing

Stainless

Brass

Aluminum

Copper

Bronze

Iron (grey and ductile)

Tool Steels

Drill Rod

Monel

Inconel

Hastaloy

Titanium

Kovar

Pinion Rod

Black Pipe

Plastics:

-PVC

-nylon

-delrin

-ultem

-peek

-acetal

-phenolic

-teflon

-nylatron

-noryl

-polyethylen uhmx

- General Specifications:

- Parts Typically Produced:

Adapters, Adjusting Bolts, Adjusting Nuts, Adjusting Screws, Bearings, Bomb Bases, Clevis’, Contacts, Couplings, Gear Racks, Hubs, Inlet Ports, Inner Flex Shafts, Outer Flex Shafts, Push Rods, Spanner Rings, Split Collars, etc.

- Industries Served:

Agricultural

Hydraulic/Fluid power

Electronics

Heavy Equipment

Automotive

Industrial

Heavy Duty Trucks

Medical Instruments

Marine Industry

Military

Brake Parts

Oil & gas industry

Plumbing

Fasteners

Injection Molding

Machinery and Equipment

Fasteners

Construction

Mass Transit

Lawn and Garden

Recreation Equipment

Heating/Refrigeration

Food/Beverage

Mining Equipment

Water Treatment